Motors for mobile and marine low voltage applications

Motors for mobile and marine low voltage applications

The electric motor is the component that actually performs the work in an electrical application. It creates movement or rotation by converting electrical energy into mechanical power. In mobile and marine applications, high demands are placed on the motor in terms of performance, robustness and ability to deliver reliable operation over long periods in demanding environments.

Choosing the right motor is crucial to the efficiency, reliability and cost-effectiveness of the entire solution. It is not just a question of the power rating on a data sheet, but how the motor performs in actual operation.

- What determines whether a motor works in real life?

- Why choose motors from ETP?

- The right motor sized for real-life operation

- Robustness and system performance in practice

- Standardised motor solutions that enable replacement and upgrading

- Frequently asked questions about motors for low voltage applications

The electric motor is the component that actually performs the work in an electrical application. It creates movement or rotation by converting electrical energy into mechanical power. In mobile and marine applications, high demands are placed on the motor in terms of performance, robustness and ability to deliver reliable operation over long periods in demanding environments.

Choosing the right motor is crucial to the efficiency, reliability and cost-effectiveness of the entire solution. It is not just a question of the power rating on a data sheet, but how the motor performs in actual operation.

What determines whether a motor works in real life?

In practice, peak power is rarely the decisive factor; what matters most is how the motor is loaded over time. The amount of torque required at a given speed, how long the motor will run continuously, and how efficient the motor is at the actual operating points are decisive factors.

ETP always bases its recommendations on the actual operating profile of the application, rather than on a single figure in a data sheet. By understanding how the machine is used in reality, it is possible to select a motor that delivers the right performance over time, without oversizing.

Why choose motors from ETP?

Wide range of motors from world-leading suppliers

ETP offers motors for mobile low-voltage applications in close cooperation with CFR and Electrified Motors.

CFR has a broad and flexible motor portfolio with extensive experience in demanding applications and the ability to make adjustments when the project requires it.

Electrified Motors offers modular motor solutions where standardised motor bodies are combined with different shafts and interfaces, providing high flexibility even for smaller volumes.

By working with several established suppliers, ETP can select the motor that is best suited to each individual project. The choice is always based on the technical requirements of the application, the available space, the operating cycle and the expected service life, not on a particular brand.

System expertise and verification for peace of mind

A motor never works in isolation. Performance, efficiency and service life are determined by the interaction between the motor, motor control and application.

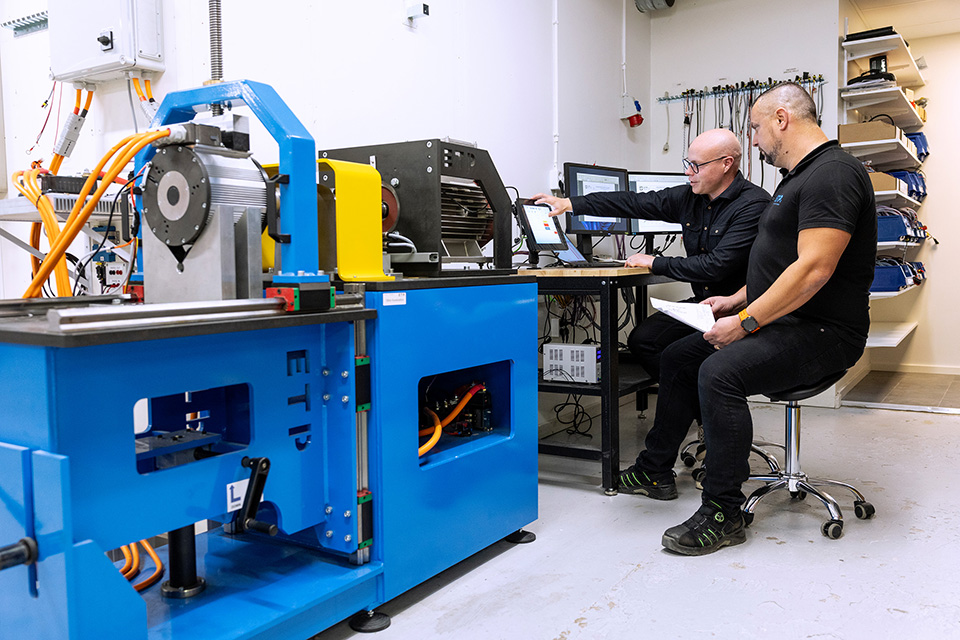

ETP has extensive experience of this interaction and the ability to test and verify the solution in-house. In our own motor test bench, the motor and motor control can be tested together under load, making it possible to optimise the whole system before commissioning. This shortens the time to a finished solution, both for new developments and when updating existing systems.

A reliable motor partner with stock and support in Sweden

Availability and operational reliability are often crucial to the overall picture. That is why ETP offers warehousing in Sweden through storage agreements tailored to customer needs.

The motors are manufactured by our established suppliers in Europe, but through ETP's warehousing and local technical support, you have access to a wide range of motors with proximity and security. The result is flexible and predictable delivery throughout the entire application life cycle.

The right motor sized for real-life operation

A common mistake in electrification is to try to replace an internal combustion engine outright. Such a 1:1 approach often leads to oversizing, higher costs and lower efficiency. To choose the right motor, you need to start from torque, speed and operating time. How much power is required, at what speed and for how long the motor should operate without getting too hot.

In many cases, it is possible to choose a smaller and more energy-efficient motor that still meets the requirements of the application. ETP helps to develop the right decision-making basis and size the solution based on real use. If necessary, we can also support with measurement and analysis of existing applications.

Robustness and system performance in practice

Motors in mobile applications must be able to withstand harsh environments and long-term operation. The solutions ETP works with are developed for heavy-duty applications and dimensioned to last for the entire life of the machine. AC and PMAC motors are virtually maintenance-free and require minimal servicing. High quality, fewer downtimes and longer service life often result in lower total costs over time.

To ensure correct performance in actual operation, we use our own motor test bench, where the motor and motor control are tested and optimised together under load before the system is put into operation. The decisive factor is not what the components can handle individually, but what performance they deliver as a whole. With the right expertise and the ability to verify the interaction internally, ETP can ensure efficiency, temperature control and operational reliability.

Standardised motor solutions that enable replacement and upgrading

In many cases, it is entirely possible to replace or upgrade a motor in an existing solution. When replacing a motor, ETP analyses the existing application and ensures that the new motor meets the same or better operating conditions. The goal is always to maintain or improve function, performance and service life without creating unnecessary changes to the system.

Frequently asked questions about motors for low voltage applications

It is the interaction between torque, speed and operating time that is decisive. The motor must be dimensioned for actual load and actual use, not just for peak power.

Yes. By using standard motors that are produced in large volumes and adapting them for the application, it is possible to combine good availability with application-specific performance and an attractive price.

AC and PMAC motors are essentially maintenance-free and require significantly less servicing than traditional combustion engines.

Get in touch with ETP

With nearly 50 years of experience developing solutions for mobile machinery, we understand what it takes to succeed. Partnering with ETP makes the transition easier – and the solution better. Contact or follow us to find out more.