Motor control for mobile and marine low voltage applications

Motor control for mobile and marine low voltage applications

Motor control is at the heart of every electrical application and determines both performance and reliability. Precise control of the electric motor ensures efficient energy conversion and stable operation. Mobile and marine applications place high demands on robustness, precision and operational reliability in varied and often demanding environments.

Motor control is at the heart of every electrical application and determines both performance and reliability. Precise control of the electric motor ensures efficient energy conversion and stable operation. Mobile and marine applications place high demands on robustness, precision and operational reliability in varied and often demanding environments.

What is motor control and how does it work in low voltage solutions?

A motor controller regulates the speed and torque of an electric motor by controlling voltage, current and frequency. The aim is to generate as much mechanical power as possible with as little electrical energy as possible, adapting to the actual conditions of the application, such as weight, load, friction and operating profile.

The motor control enables smooth starts and stops, precise speed control from very low to high speeds, and continuous monitoring of temperature and load. The result is better control, higher efficiency and more predictable operation in environments where energy availability is often limited.

Three parameters are always key. The motor should:

- deliver the right torque for the task,

- do so with high efficiency,

- be able to be regulated stably and predictably across the entire working range.

Motor control is also a key part of the application's functional safety. By monitoring temperature, current and load, the system can limit operation, initiate safe stops and prevent situations that could damage the machine, equipment or surroundings. When configured correctly, the motor control helps to comply with applicable regulations for low-voltage applications in mobile and marine environments, while also simplifying documentation and verification.

Why choose motor control from ETP?

World-leading technology from ZAPI

ETP works with motor control from ZAPI in the low-voltage segment. This technology has been developed specifically for mobile and marine applications where robustness, compact design and reliable operation are crucial.

The motor controllers are developed and manufactured in Europe and have been proven in applications exposed to vibrations, moisture, salt, dirt and large temperature variations. For customers who already have electrical systems in operation, this represents a technically mature and safe choice.

Deep in-house expertise and verified performance

ETP has extensive experience in motor control and electrified low-voltage solutions. We work daily to configure systems based on load, operating cycles, available energy and requirements for performance, energy efficiency and service life.

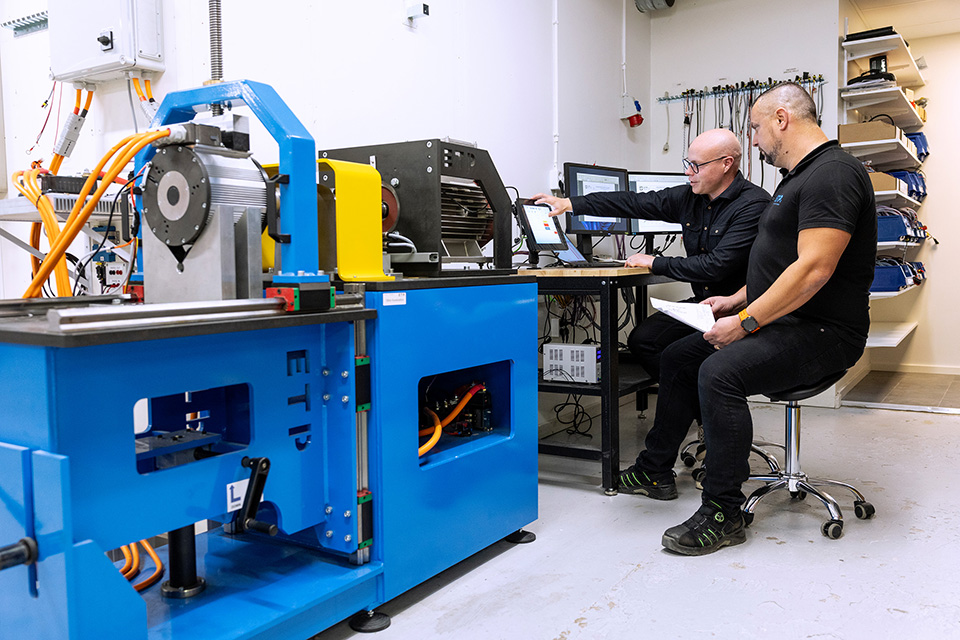

The difference between a motor control system that works and one that is optimised rarely lies in the hardware. It lies in how well the solution is adapted to the actual use of the application. We have invested in our own motor test bench where the motor and motor control are tested together under load to optimise the motor control for the unique application. Here we verify and optimise torque control, efficiency and speed control before delivery.

This is particularly important for modern PMAC and PMSM motors, where correct adjustment is crucial for both performance and operational reliability. All configurations are documented and can be reproduced, providing a secure and repeatable solution even in series production.

A reliable supplier of motor control with warehouses in Sweden

Motor control is a critical component in mobile and marine applications, where availability is often crucial to the overall operation. That is why ETP offers warehousing in Sweden through stock agreements tailored to customer needs. This results in shorter delivery times, quick access to replacement units and reduced risk of downtime.

The hardware is manufactured by ZAPI in Italy, but by signing a stockkeeping agreement with ETP, you can access world-leading technology with stockkeeping and support in Sweden. The result is secure and flexible delivery throughout the entire life cycle of the solution.

Examples of mobile and marine applications

ETP supplies motor control systems for a range of mobile and marine low-voltage applications where precision, reliability and robustness are essential. Examples of areas of application include mobile material handling equipment, special-purpose vehicles, municipal maintenance equipment and applications where precise manoeuvring, controlled acceleration and protection of mechanical components are crucial.

With integrated diagnostics, temperature monitoring and safe stop functions, the motor control also contributes to a better operator experience, higher safety and longer equipment life.

The motor controllers are developed and manufactured in Europe and have been proven in applications exposed to vibrations, moisture, salt, dirt and large temperature variations. For customers who already have electrical systems in operation, this represents a technically mature and safe choice.

Standardised motor control that allows switching

In the low-voltage segment, motor control is largely based on established industry standards. Voltage levels, current levels, pulse generators and basic functions follow common principles regardless of manufacturer.

Motor controllers with corresponding power and voltage ratings therefore essentially perform the same task. The differences mainly lie in the connection, configuration and how the motor controller is integrated into the system. With the right expertise and methodology, it is entirely possible to replace an existing motor controller without changing the basic architecture of the application.

Is it possible to change the motor control in a ready-made solution?

Yes, in many cases this is entirely possible. When replacing a motor, we analyse the existing application, select the right motor control for the current voltage and power class, and adapt the wiring diagram, cabling and control system so that the solution works optimally. The functions are basically the same, but the motor control is configured and optimised to suit your specific application.

ETP provides support throughout the entire process, from selecting the right product to configuration, testing and verification. For customers who already have a functioning low-voltage solution, we can offer access to world-leading motor control with reliable deliveries without having to rebuild the entire system.

Frequently asked questions about motor control

Motor control is the component that regulates the speed, torque and operation of an electric motor by controlling voltage, current and frequency. In mobile and marine applications, motor control is crucial for energy-efficient operation, precision and safe functioning.

Motor controllers for low-voltage applications can vary in terms of both hardware quality and how well they can be adapted to the application. Robustness, thermal performance and reliability in

demanding environments vary between different brands and are crucial to function and service life.

ETP works with proven standard products from one of the world's leading manufacturers. Through the right configuration, integration and testing, the same standard product can be adapted for completely different operating profiles, loads and functional requirements. The result is a solution that combines industrial quality and availability with application-specific performance.

Yes, in many cases it is possible to change the motor control without changing the motor, provided that the correct voltage level, power class and configuration are selected and that the system is verified after the change.

Get in touch with ETP

With nearly 50 years of experience developing solutions for mobile machinery, we understand what it takes to succeed. Partnering with ETP makes the transition easier – and the solution better. Contact or follow us to find out more.