Low-voltage solutions

For electric light-duty applications with a focus on energy efficiency and customisation

Electrify your mobile application with ETP

Low-voltage solutions form the foundation for many modern electrified applications, particularly where safety, simplicity, and compact systems are essential. We offer proven and flexible low-voltage systems that are perfectly suited for mobile and marine applications with lower power requirements.

ETP has been working on the electrification of mobile applications for several decades. Smaller machines for material handling and indoor applications have led the way in this development, but demand is now growing rapidly in other areas as well.

Machines used for city maintenance and smaller construction applications are increasingly being electrified. At the same time, technological advances are opening up new opportunities in e-mobility. With extensive experience in low-voltage systems, ETP designs precise, energy-efficient solutions optimised for each customer’s application.

Johan SkoglundSales Manager ETP

Low voltage for efficient and safe electrification

Low-voltage solutions cover electrical systems up to 120 VDC. This technology is well established in applications such as forklift trucks, work machines and indoor applications, where silent operation, zero emissions and high levels of personal safety are essential.

Unlike high-voltage systems, low voltage does not require special electrical qualifications, making installation, service and maintenance simpler. The technology also offers high flexibility and excellent energy efficiency, making low-voltage solutions an attractive choice for a wide range of applications.

We supply complete systems or individual components – always tailored to your needs:

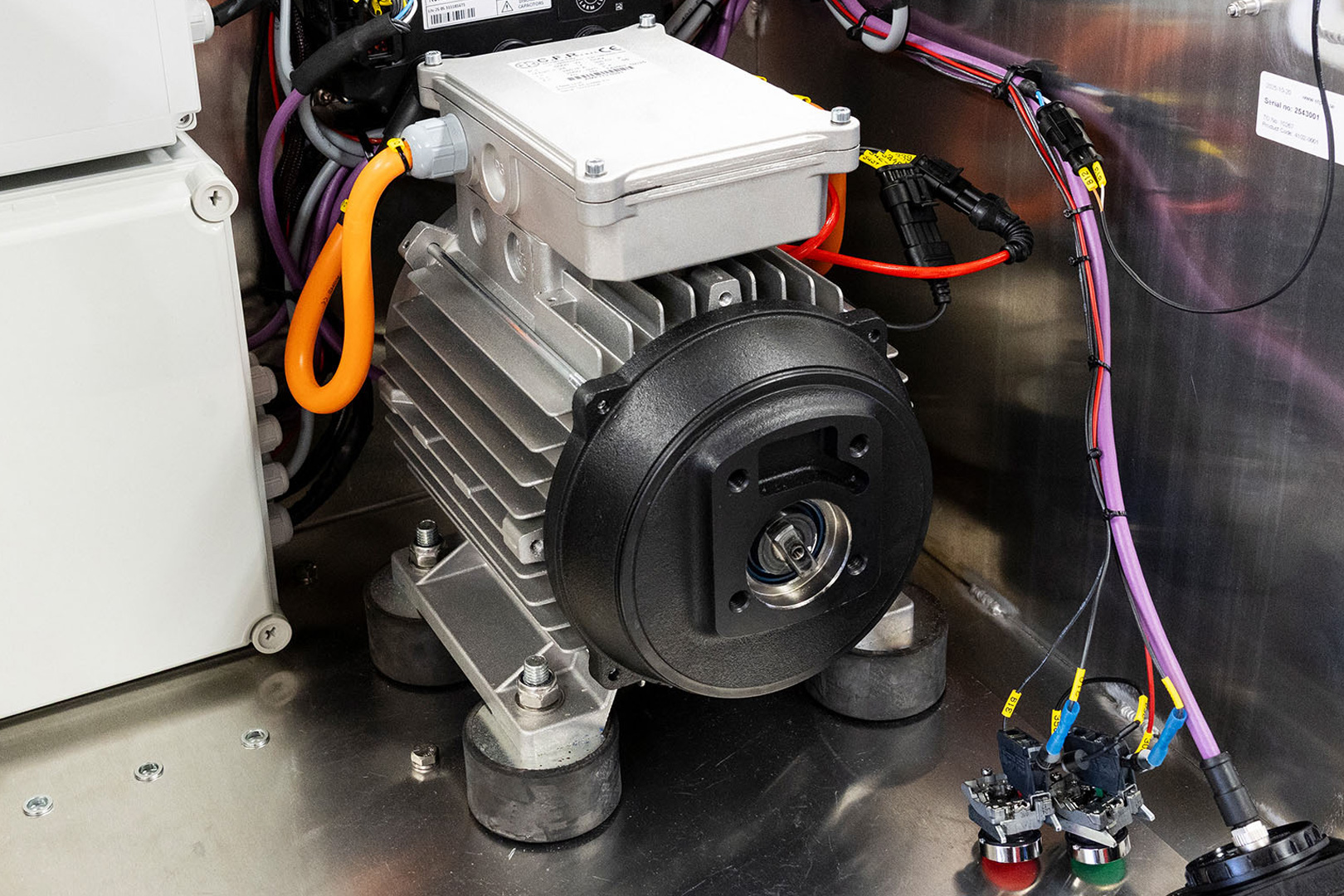

- Electric motor optimised for compactness and efficiency

- Inverter for optimal motor operation

- Lithium-ion battery that are reliable and easy to integrate

- Charger adapted to the application and battery

- Control system and display with clear information and intuitive control

- Telematics and monitoring for insight, follow-up and remote support

- Integration that ensures everything works as a whole

System design optimised for real-world operations and the end user

Designing a low-voltage system requires the same level of precision as a high-voltage system. Our role is to dimension each system precisely to the application’s requirements – delivering the right power, the right operating time and the right user experience.

We ensure that every component works seamlessly together and that the solution delivers reliable performance over time. The result is a system that is safe to own, easy to maintain and built to perform day after day.

It’s about more than components. We take full responsibility for delivering complete systems that work from the start. For our customers, this means the first machine is often production-ready – saving time, reducing risk and accelerating the path to market.

Johan Skoglund

Sales Manager, ETP

Engineering low-voltage systems for safety, efficiency and performance

Developing effective low-voltage solutions is about balancing safety, simplicity and performance. At ETP, we design systems tailored to the specific requirements of each application and the customer’s objectives. Through smart technology choices, optimisation and integration, we deliver solutions that are energy-efficient, cost-effective and easy to implement.

Each system begins with a thorough analysis of the machine’s power and energy requirements. Based on this analysis, we develop a concept design and initiate the dimensioning process to select the most suitable motor or combination of motors.

We work with three main technologies in low-voltage systems: DC, AC and synchronous permanent magnet (SPM) motors, selected according to how the application will be used. DC motors are typically used at lower power levels, where simplicity and cost are the main priorities. AC motors are chosen when high controllability is required, from around 3 kW and upwards, the cost of AC and DC motors is generally comparable. SPM technology is used when high efficiency and a compact design are essential. Regardless of the technology selected, the combination of proven components and modern control systems makes our solutions a safe and reliable choice for everything from small mobile machines to marine systems.

Battery energy density is one of the key challenges in electric systems, and its characteristics require all surrounding components to be optimised with the battery in focus. By carefully analysing the energy and power requirements of each function, we dimension the system to achieve the optimal balance between energy efficiency, performance and cost. In many cases, using several smaller motors results in higher overall efficiency and reduced energy demand.

Our low-voltage solutions are based on lithium-ion batteries offering long service life, high safety and customised control. The result is flexible, reliable systems that combine high technical performance with straightforward integration into the customer’s application.

Our low-voltage solutions are always developed with the application requirements in mind. By optimising each system based on energy efficiency, performance and price, we create solutions that provide maximum uptime, reliability and customer value.

Emil Westerlind

Head of R&D

Electrification, hydraulics and electronics in a powerful combination

ETP and HydX combine cutting-edge expertise in electrification, hydraulics and electronics. Together, we deliver complete solutions that meet requirements for performance, precision and sustainability.

Read more on the HydX websiteRead more about our other technology areas

Want to know more about our low-voltage solutions?

Robin von Dorrien

Sales Engineer

Joakim Paulsson

Sales Engineer

Get in touch with ETP

With nearly 50 years of experience developing solutions for mobile machinery, we understand what it takes to succeed. Partnering with ETP makes the transition easier – and the solution better. Contact or follow us to find out more.